I am sitting here musing about the recent industry event I attended and some of the frustration felt by the oil and gas community about decommissioning in the North Sea, in particular the lack of progress in North Sea decommissioning projects starting.

“If you keep deferring it and more of the supply chain suffers and fails, there’s not going to be enough of it here to do it economically in the future”

Barry MacLeod, MD Bibby Offshore UK, Decom Offshore 23rd May 2018

It appears the main obstacle is a lack of a ‘prize’. There is a perception that this is a regulatory obligation, that the process will lead to excessive costs and only the contracting community is set to benefit, not the tax payer or operator. To a certain extent I would say that this is true, however, I’d also like to express an opinion that that may change some industry ‘mindsets’.

It strikes me that when assets are set to be decommissioned the current industry thinking is that they need to be immediately disposed of. There is a ‘rush’ to get on with the task at hand and immediately take the asset straight to disposal. So, when the asset reaches Cessation of Production (COP) it is treated as waste that must be disposed of. This means that at COP, the assets and all component parts immediately become a liability to the Operator and the best way is to dispose of these in the quickest and most efficient manner. Why is this the case?

I believe this approach is perhaps too hasty, leaving very little wriggle room to repurpose some of the asset to create value to others further down and across the broader supply chain. We pride ourselves within the industry on how we’ve met the challenges of production within the harsh environment of the North Sea. These assets are highly engineered and made from some the most durable products on the market. Surely this must mean that at least some of these parts can be put to use elsewhere in the industry or in the broader economy. So, if this is the case then, they must have some value. A thought I believe was echoed by Graeme Fergusson of Decom Energy when he stated:

“…if operators can clearly identify when an asset is in terminal decline, there is an opportunity to be more efficient in the decommissioning process.”

Graeme Fergusson, Director Decom Energy, Decom Offshore 23rd May 2018

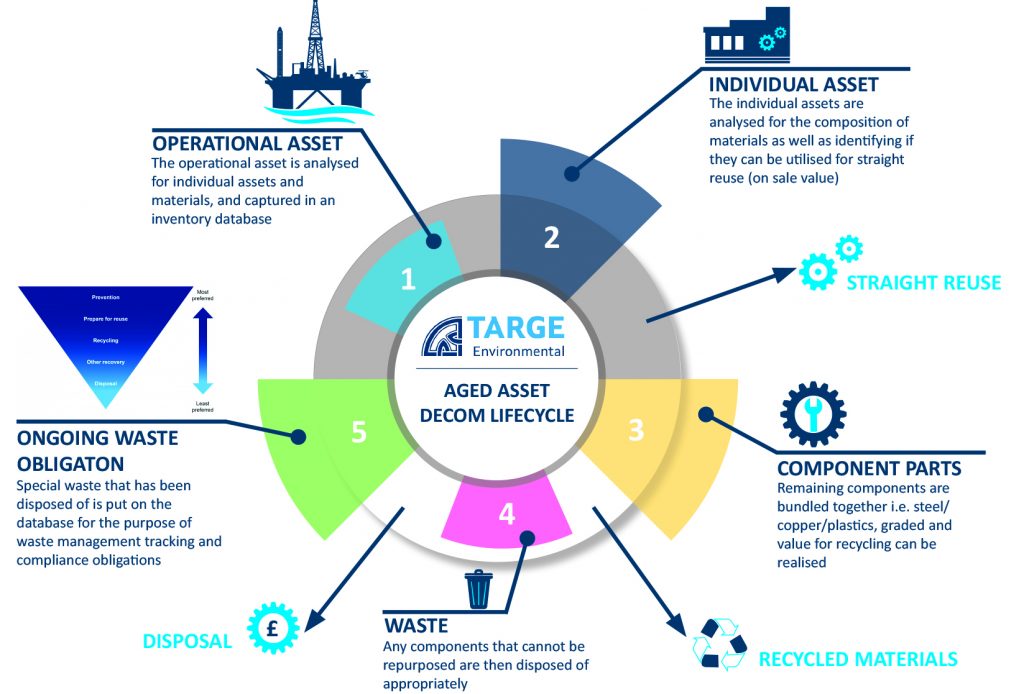

These are still assets, albeit assets in decline, but not yet terminal. Only after a robust investigation and creation of an active asset material management plan should they be considered a liability or waste. Note the use of the word “material”, not “waste” management plan. Our business has been working on this model of working for a number of years with relative success, as shown at the top of this blog.

Now, I’m pretty sure that you would have seen this model before. Perhaps we have been applying it to our customers more robustly, but we can demonstrate a 90% topside mass reuse/recycle/other recovery. That’s circa 21,000 tonnes of steel to be recycled, with a scrap metal rate for carbon and stainless steel that would be worth £m’s. Many precious metals and valuable equipment have also been identified as part of this process and are currently being reused or recycled within oil and gas or to other industries.

So perhaps the “prize” should be a share in how much we can recover, how much we can reuse. That means there is value for all of the key stakeholders that can be recognised. I know that contractor models for plant/machinery and equipment can be complicated but, it doesn’t mean it can’t be done. There have been some good examples recently, one that I can think of straight off the bat is the use of tubulars for construction of the new Aberdeen Exhibition and Conference Centre.

I would really appreciate your views on the subject and whether you think that this could be a way forward for our burgeoning industry.

Ciara McGarry, Principal Consultant, Targe Environmental